HITS-X Series - Características

High-Speed Impact Testing Machines

- Descripción general

- Características

- Aplicaciones

- Especificaciones

- Descargas

- Configuración

- Opciones

- Soporte

CAE Analysis Simulations Baseline Data for Product Design

To reduce weight and fuel costs in the automotive industry and other transportation equipment markets, the use of plastics and composite materials has increased. Due to the superior workability of plastics compared to metals, many parts that were made of metal are now being made of plastics. However, plastics are not as resistant as metals to heat and shock. For this reason, new materials are continually being developed and these materials need to be tested.

Additionally, in order to improve the efficiency of development, the manufacturing technique is simulated during the design stage, so the accuracy of these processes is very important.

An improvement in the simulation accuracy can be expected by making use of yield stress, maximum test force, and energy obtained through high-speed tensile testing.

Equipped with State-of-the-Art Technology

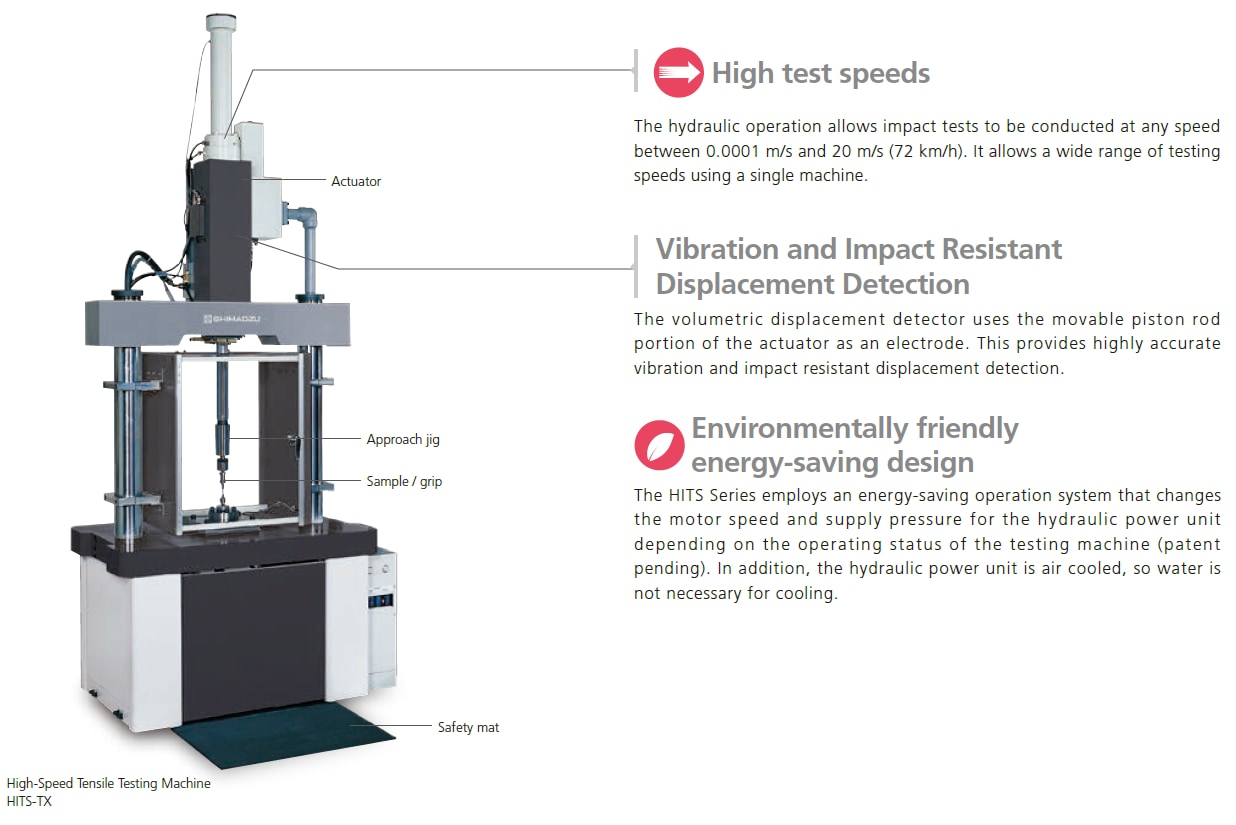

High test speeds

The hydraulic operation allows impact tests to be conducted at any speed between 0.0001 m/s and 20 m/s (72 km/h). It allows a wide range of testing speeds using a single machine.

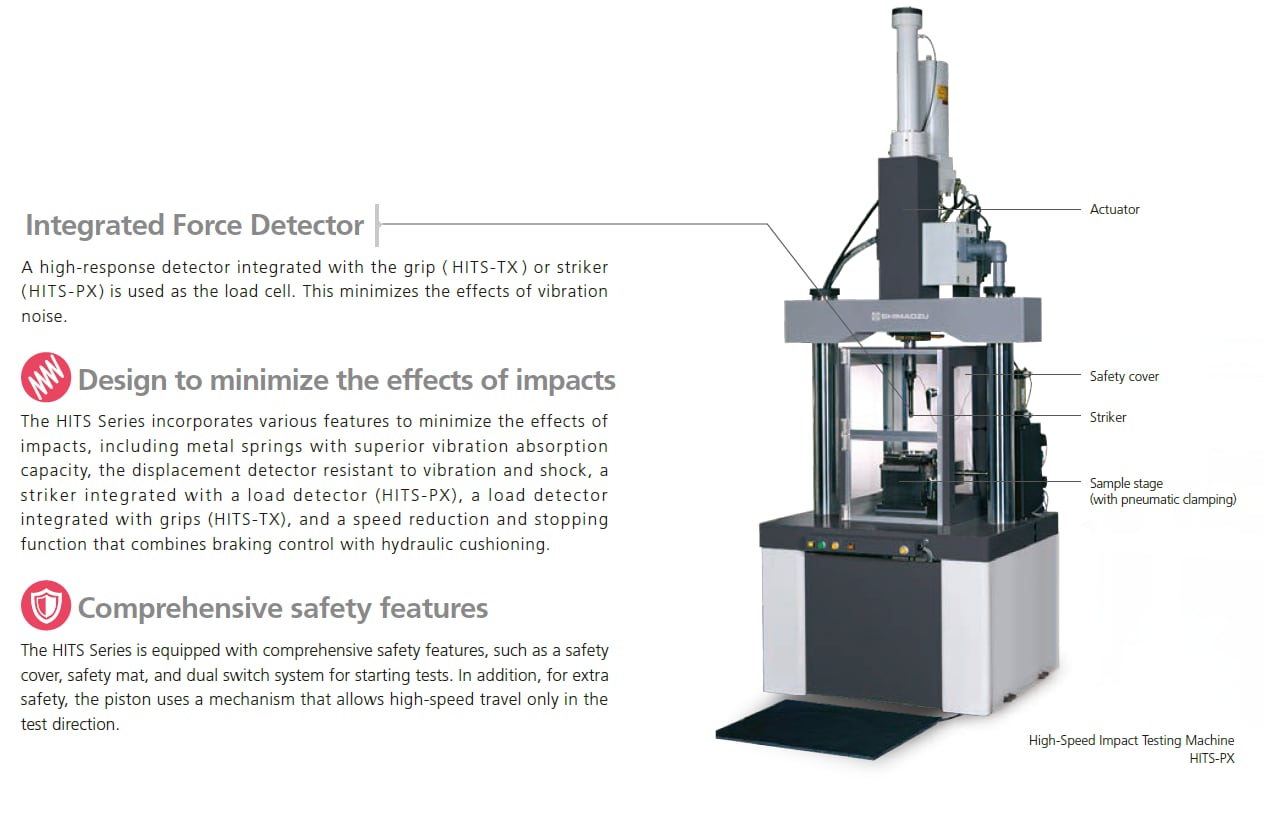

Design to minimize the effects of impacts

The HITS Series incorporates various features to minimize the effects of impacts, including metal springs with superior vibration absorption capacity, the displacement detector resistant to vibration and shock, a striker integrated with a load detector (HITS-PX), a load detector integrated with grips (HITS-TX), and a speed reduction and stopping function that combines braking control with hydraulic cushioning (patent pending).

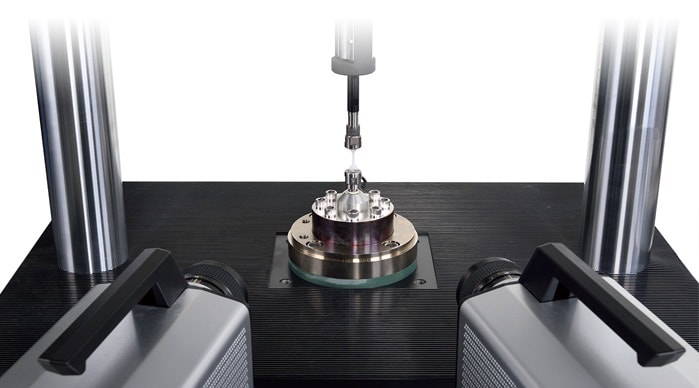

Specialized approach jig (HITS-TX)

Allows target speed to be reached rapidly.

State-of-the-art software

The software uses standard Windows 10 wizard format to allow intuitive and simple operation even for beginners. The software provides information such as load-displacement curve, maximum test force, displacement, energy, and inclination. Advanced processing, such as overlaying results from multiple tests or statistical analysis are standard functions.

Environmentally friendly energy-saving design

The HITS Series employs an energy-saving operation system that changes the motor speed and supply pressure for the hydraulic power unit depending on the operating status of the testing machine (patent pending). In addition, the hydraulic power unit is air cooled, so water is not necessary for cooling.

Comprehensive safety features

The HITS Series is equipped with comprehensive safety features, such as a safety cover, safety mat, and dual switch system for starting tests. In addition, for extra safety, the piston uses a mechanism that allows high-speed travel only in the test direction.

Temperature dependency for high-speed behavior (optional)

Information on the temperature dependency for specimens’ high-speed behavior can be obtained using the optional thermostatic chamber (-40 to +150°C).

Controller 4870 and Software Dedicated for the High-Speed Impact Testing Machines

Dedicated Controller with Start Interlock System Incorporating High-Response Amplifier

Reliably controls the testing speed during high-speed impact tests, from start to finish. To ensure operator safety during impact testing, systems are designed to use hardware for manual operations, starting tests, and stopping the machine.

High-Speed Impact Testing Software

Dedicated High-Speed impact testing software for outstanding user friendliness

The software, which is specially designed for High-Speed impact testing, uses standard Windows 10 wizard format to allow intuitive and simple operation even for beginners. The software provides information such as load-displacement curve, maximum test force, displacement, energy, and inclination. Advanced processing, such as overlaying results from multiple tests or statistical analysis are standard functions. The software consists of two parts: the “Testing” and “Data Processing” components. Since both software components can be opened simultaneously, data can be processed while tests are being performed, allowing testing to be executed efficiently.

Home

Test Execution

Testing software

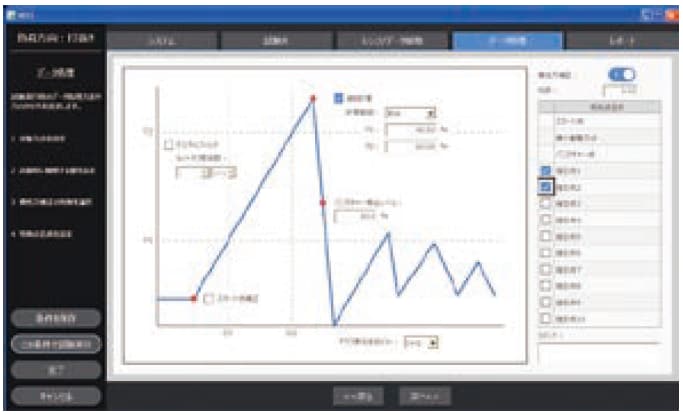

- Setting parameters

Test parameters are set via a wizard-style interface. Parameters can be entered via a dialog format. - Testing

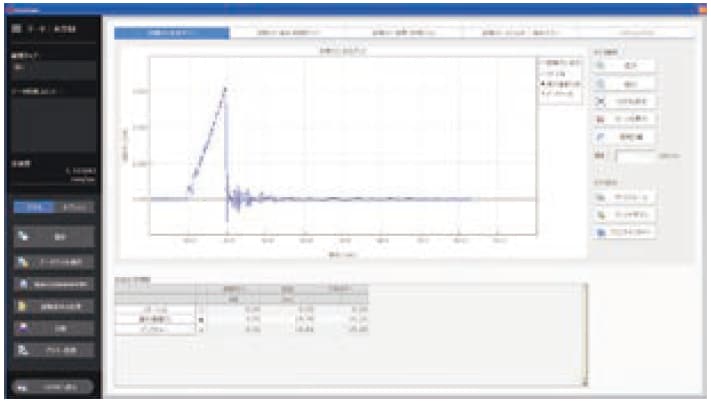

The testing screen shows measurement values with actually used and, online graphical displays of test results, and includes a measurement start button.

Parameters Setting Screen

Testing Screen

Data Processing Software

- Data processing functions

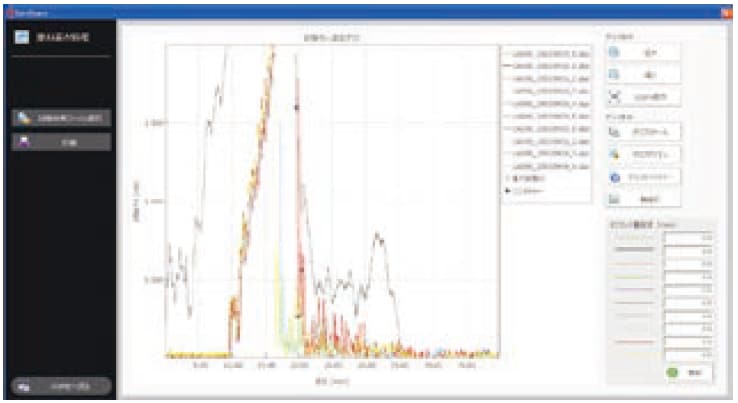

The software displays summary data for the maximum test force, corresponding energy and displacement, at specified points, as well as inclination. It also provides graphs, which include a smoothing feature. - Multiple data overlaying and statistical processing functions

Up to ten test data curves can be overlaid. Statistical data for multiple data sets, such as mean values and standard deviation, can be obtained. - Report printing functions

Numerous printing functions, such as overlaying graphs or indicating characteristic values at the point of maximum test force or specimen fracture, are available.

[ Data processing screen ]

( High Rate Tensile Testing Machine HITS-X )

[ Data processing screen – overlaying data ]

( High Rate Tensile Testing Machine HITS-X )