TOC system for Pharmaceutical production

Cleaning Validation TOC System

Currently, there is a strong demand for the introduction of development, manufacturing and control systems in accordance with GxP at pharmaceutical manufacturing and development sites. And, in pharmaceutical manufacturing, water quality control in line with the GxP guidelines is also required for water used as raw materials and rinsing water.

The TOC-V/L Series conforms not only with USP (United States Pharmacopeia) and JP (Japanese Pharmacopeia) but also with other world standards (EPA, ASTM, JIS, ISO, etc.), and demonstrates its outstanding performance in TOC control and cleaning validation of pharmaceutical water.

Supporting the Control of Impurities in Pharmaceutical Water Compliant with Pharmacopeia in Each Country

Organic impurities in pharmaceutical water are controlled by using TOC in the Pharmacopeia in the United States and the EU.

TOC is also used as the general test method in Japanese Pharmacopeia. The TOC-V/L series is compliant with Pharmacopeia in these countries.

The following is stipulated in general test methods according to the Japanese Pharmacopeia:

- The TOC analyzer must be able to measure TOC at a concentration of 0.05 mg/L.

- Calibration must be able to be performed using potassium hydrogen phthalate.

- The collection ratio of sodium dodecylbenzene sulphonate solution with a TOC concentration of 0.5 mg/L must be 90% or more.

Furthermore, according to the Japanese Pharmacopeia, the following pharmaceutical water must be controlled by TOC:

- Water

- Of water for injection, water that is purified by ultra-filtration methods for adjustment of injections

Moreover, according to reference information "Water Quality Control of Pharmaceutical Water," water control by TOC is recommended for pharmaceutical water, such as water for injection or purified water. Even for water used as raw water for manufacturing pharmaceuticals, the implementation of TOC measurement-based water quality control with appropriate criteria values established in each manufacturing facility is recommended. Though TOC measurement as stipulated in the Water Supply Act is required for water, this act also requires that water containing suspended organic substances is measured in case suspended substances should by chance enter the tap water. The TOC-VCPH/CSH, which uses the 680 °C catalytic combustion oxidation method, can completely oxidate and separate suspended substances that are potentially contained in water. It also has sufficient sensitivity at a detection limit of 4 µg/L for measuring pharmaceutical water, thus enabling ideal water quality control.

Pharmaceutical water management is available in both combustion oxidation method and wet oxidation method

| Catalytic combustion oxidation method | Wet Oxidation/NDIR Method |

|---|---|

|

|

Equipment Validation

The GLP/GMP guidelines also require validation of analytical instruments.

For the TOC-V/L series, validation is conducted at installation, and "IQ" documentation to certify that installation has been conducted properly and "OQ" documentation that outlines procedures for periodic checking of the system are provided to support validation.

Cleaning Validation by Swab Method

In pharmaceutical manufacturing facilities, "residue evaluation testing" must be performed to scientifically prove that pre-product or detergent residue, external contaminants, etc. are at pre-determined allowable limit values or lower.

Key points in residue evaluation testing are analysis method, allowable limit values and sampling method.

Of the sampling methods, the swab method is highly appraised and recommended by the FDA and Japan's Ministry of Health, Labor and Welfare. By this method, a swab is used to physically wipe a fixed area on the surface of equipment to take up attached residue for analysis, allowing attached insoluble residues to be physically wiped off and sampled. As a result, measurement can be performed quickly and even more accurate evaluations can be made.

When used in combination with the SSM-5000A Solid Sample Combustion Unit, the TOC-V/L series instrument can directly measure swabs without the need to extract residue from them and transfer it to water for measurement, thus rapidly speeding up the measurement process and ensuring greater accuracy.

Easy wiper-S

Easy wiper-S

Swab Material Specialized for SSM-5000A Solid Sample Combustion Units Used with TOC-V and TOC-L Total Organic Carbon Analyzers

- The fibrous form of the swab material resists unraveling and is less likely to leave swab material fragments on wiped surfaces.

- The swab is easier to place in sample boats after swab sampling.

- Surfaces can be wiped more easily using a small amount of purified water.

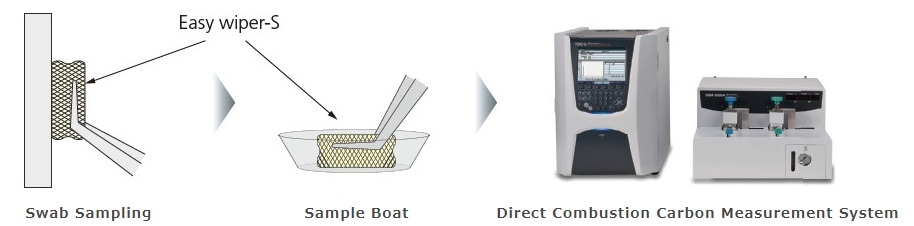

Swab Sampling - Direct Combustion Method

The swab sampling − direct combustion carbon measurement method uses a direct combustion carbon measurement system to measure carbon by wiping the interior surfaces of manufacturing equipment with an Easy wiper-S inorganic quartz glass fiber swab material. The Easy wiper-S with the residual substances attached from the wiped surface is placed into a sample boat. Then the carbon content is measured directly in the boat using the direct combustion carbon measurement system, which combines an SSM-5000A solid sample combustion unit with a TOC analyzer. The results are shown in Table 1. Regardless of the solubility or insolubility of each substance, the recovery rate was about 100% for all substances.

| Substance | TC value [μg C] | Recovery Rate [(TC value - blank) / theoretical value)] |

|---|---|---|

| Blank |

0

|

- |

| Tranexamic acid |

207

|

104% |

| Anhydrous caffeine |

207

|

104% |

| Isopropylantipyrine |

201

|

101% |

| Nifedipine |

208

|

104% |

| Rinderon ointment |

193

|

96.7% |

| Petrolatum |

207

|

104% |