Servopulser

- Testing Machine Retrofits

- Autograph Universal Testing Machines

- Hydraulic Universal Testing Machines

- Servopulser

The functions and performance of outdated testing machines can be improved by changing the controller.

4890 ControllerRetrofit

- Greatly expandable from basic fatigue tests through to special tests and data analysis

- Fracture toughness test, thermal fatigue test and data processing can be handled by dedicated software.

4830 ControllerRetrofit

- The replacement timing of the servo valve, oil and oil filter are notified by measuring operating time.

- Dedicated software can correct waveform distortion. This means that, even when specimen characteristics and changes over time have distorted the waveform, amplitude and phase are corrected to ensure accurate test results.

- An oscilloscope is no longer required.

Waveforms are displayed on a color LCD.

Retrofit Applicable Models

Testing machines that use Shimadzu 4800, 4825, 4850, 4875, 4880, and 48000 controllers.

Other manufacturers' testing machines also can be retrofitted. Contact your Shimadzu representative for details.

Detector Rating and Unit/Calibration Information Read Automatically

- Setting of rating and unit and calibration work no longer required

- Testing can be conducted safely without mistakes when multiples cells or extensometers are used.

Detailed Alarm Settings Increase Safety

- Digital Load Limiter restricts overloads.

- Overlimits for each detector and low amplitude/control deviation can be set, and waveform stop, hydraulic power supply stop, stroke hold, and unload for after an alarm occurs can be selected to ensure safe operation.

Auto-tuning Function

- Optimum parameters for control can be automatically obtained and set by setting the specimen in place and applying a preload.

Range Setting No Longer Required for Test Force and Displacement Measurement

- Measurement ranges no longer need to be checked before testing. High precision is also ensured when testing by a test force with a small amplitude after having applied a large test force.

Testing by Waveforms Saved to File

- Actual waveforms measured by other methods can be used for conducting tests. This achieves endurance testing in the actual operating environment.

Substantial Range of Other Functions

- Auto-gain control (AGC) function for holding peak values of repeat waveforms at the target value

- In addition to repeat loads, complex program load settings can be made while verifying them graphically.

- Conditions can be set using wizards just as in Excel to ensure simple, mistake-free setup.

- During testing, your cellphone can be notified by mail, for example, at fixed time intervals, when status changes or when the specimen breaks.

Partial Additions to Instrument Hardware

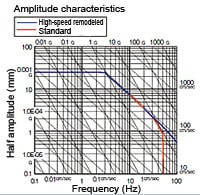

The test frequency of your installed instrument can also be further extended by hardware additions. The example on the right shows frequency characteristics when a standard system has been modified to be 100 Hz-compatible.

General Precautions When Buying Retrofit Products

- The original testing machine stays as it is, so you cannot expect any improvements in performance.

- Please check with use beforehand about the product already installed. This will sometimes require a preliminary visit by us.

- Retrofits sometimes do not meet customers' expectations depending on the condition of the already installed product such as added on options and modifications.

- During a retrofit, nonconformities are sometimes found in parts other than those covered by the retrofit. Additional fees will be charged in this case.

- Also note that when retrofitting ultra micro hardness testers, the tester must be taken back to the factory for modification.

* Appearance and specifications are subject to change without notice.