Open-Hole Tensile Strength Test of Carbon Fiber Reinforced Plastics (Reference Standards: JIS K 7094:2012 / ASTM D 5766:2010)

Recently, alternative lightweight materials instead of conventional metal materials have been used in structures that require mechanical reliability.

This is because these alternative materials make the products lighter and reduce transportation weight which, in turn, reduces carbon dioxide emissions during transportation. Complex fiber reinforced materials using carbon fibers such as carbon fiber reinforced plastics (CFRPs) are extremely strong and light.

For these reasons, they are now widely used to manufacture aircraft parts. It is expected that they will be used more in all types of products, including automobiles, in order to make the products lighter.

This experiment introduces a case of testing open-hole tensile strength of CFRPs.

Measurements and Jigs

CFRPs show a high tensile strength and generate a strong fracture impact. During testing, it is recommended to use a testing machine and jigs having sufficient capacity for the maximum test force of the sample.

In this test, measurement was performed on the following sample.

Dimensions: L (mm) x W (mm) x T (mm) = 150 x 36 x 2.5, Pore diameter: 6 mm, stacking method [45/0/-45/90]2s.

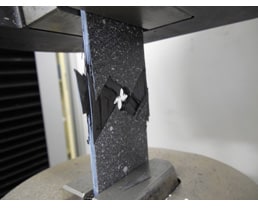

Fig.1: Open-Hole Tensile Strength Test

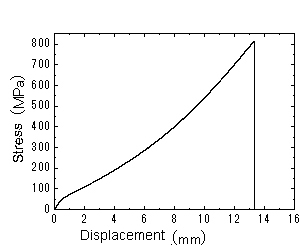

Fig. 2: Relationship Between Stress and Displacement

[ Table 1 Test Conditions ]

| Item | Setting Value |

| Test Speed | 1.5mm/min |

| Grip spac | 70mm |

[ Table 12 Test Results (Mean Value) ]

| Sample Name | Open-Hole Tensile Strength |

| CFRP open-hole test sample | 812.8Mpa |

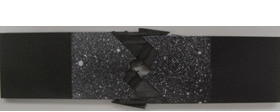

Fig. 3: Fractured Sample

| Testing machine | AG-Xplus |

| Load cell | 100kN |

| Test jig | 100 kN non-shift wedge-type grips, Trapezoidal file teeth for complex materials |

| Software | TRAPEZIUM X (Single) |

Precision Universal Tester

AGS-X Series

Convincing Cost Performance

Smarter Work Space

Improved Safety

Quest for Convenience