CFRP Research and Development - CFRP Tensile Test Breakage Observations via High-Speed Video Camera -

CFRP Tensile Test Breakage Observations via High-Speed Video Camera

In the development of composite materials, in addition to performing static strength tests to verify functionality, it is becoming increasingly necessary to assess impact strength and the breakage progression process to ensure dynamic safety. Accordingly, observations were made of the tensile impact breakage of a CFRP test specimen using a combination of a high-speed video camera and a high-speed tensile impact tester.

Example of CFRP Tensile Test Breakage Observation

The high-speed video camera was positioned approximately 450 mm in front of the test specimen. Filming was then performed using an external trigger system, with a filming start signal, synchronized with the tensile load, delivered to the camera from the tester. A strobe illumination system synchronized to the filming timing was used.

Example of CFRP Tensile Test Breakage Observation

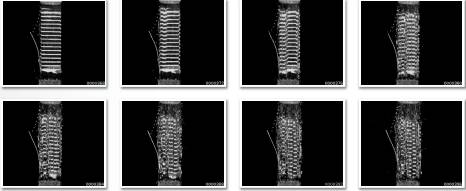

The image shows eight consecutive frames. There is a 4 microsecond gap between frames. By combining a high-speed video camera with a materials tester, it is now possible to simultaneously evaluate the physical properties of the material and observe the breakage state, thereby supporting a wide range of materials development, from functional resins themselves to composite materials.

Observations of the breakage of a CFRP material are introduced here as well.

Observation of Failure in CFRP Materials

Impact Testing

The HITS-T10 Hydroshot High-Speed Tensile Testing Machine allows tensile testing of various materials at any speed up to a maximum 72 km/h (20 m/s) providing a wide range of dynamic strength information, such as stress-strain curves, maximum test force, energy, and displacement data.

High-Speed Video Camera

Takes 100 consecutive images at up to one million frames per second. Maintains a constant 312 x 260 pixel resolution up to the maximum frame rate. A single PC can control synchronous imaging with a maximum of four cameras to observe the phenomena from multiple viewpoints. Synchronizing imaging with a tensile testing machine enables comparative observations of stress data and high-speed images.